opening work in process inventory formula

Deduct the cost of raw material from this figure that is on hand at the end of the accounting period to determine the costs of materials consumed during the accounting. The reason is that it is expected that it will be sold in the coming months.

Finished Goods Inventory Formula Calculation Turnover

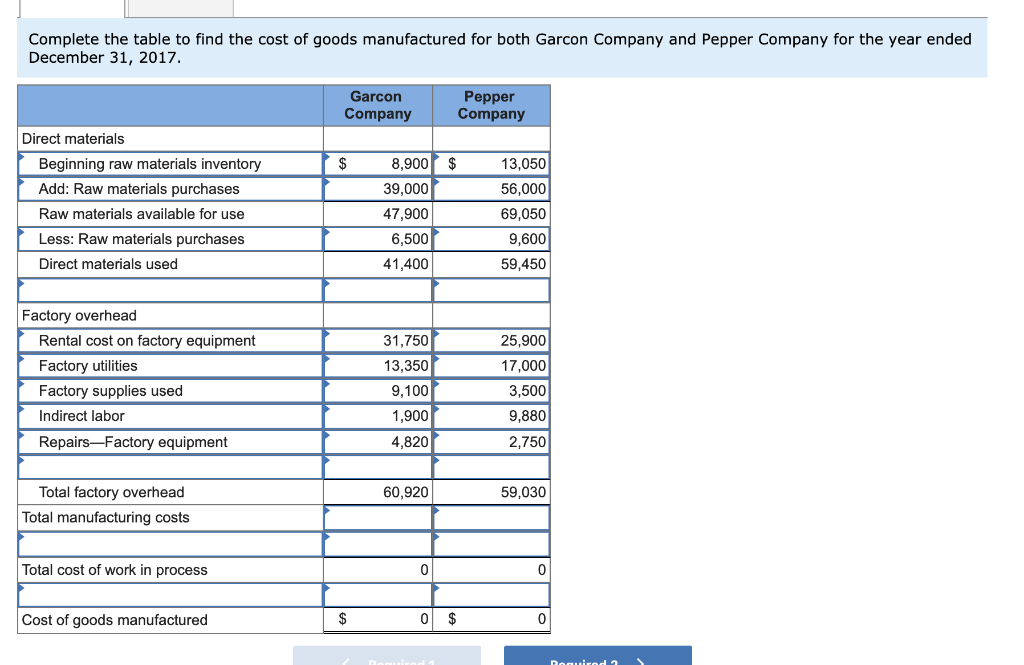

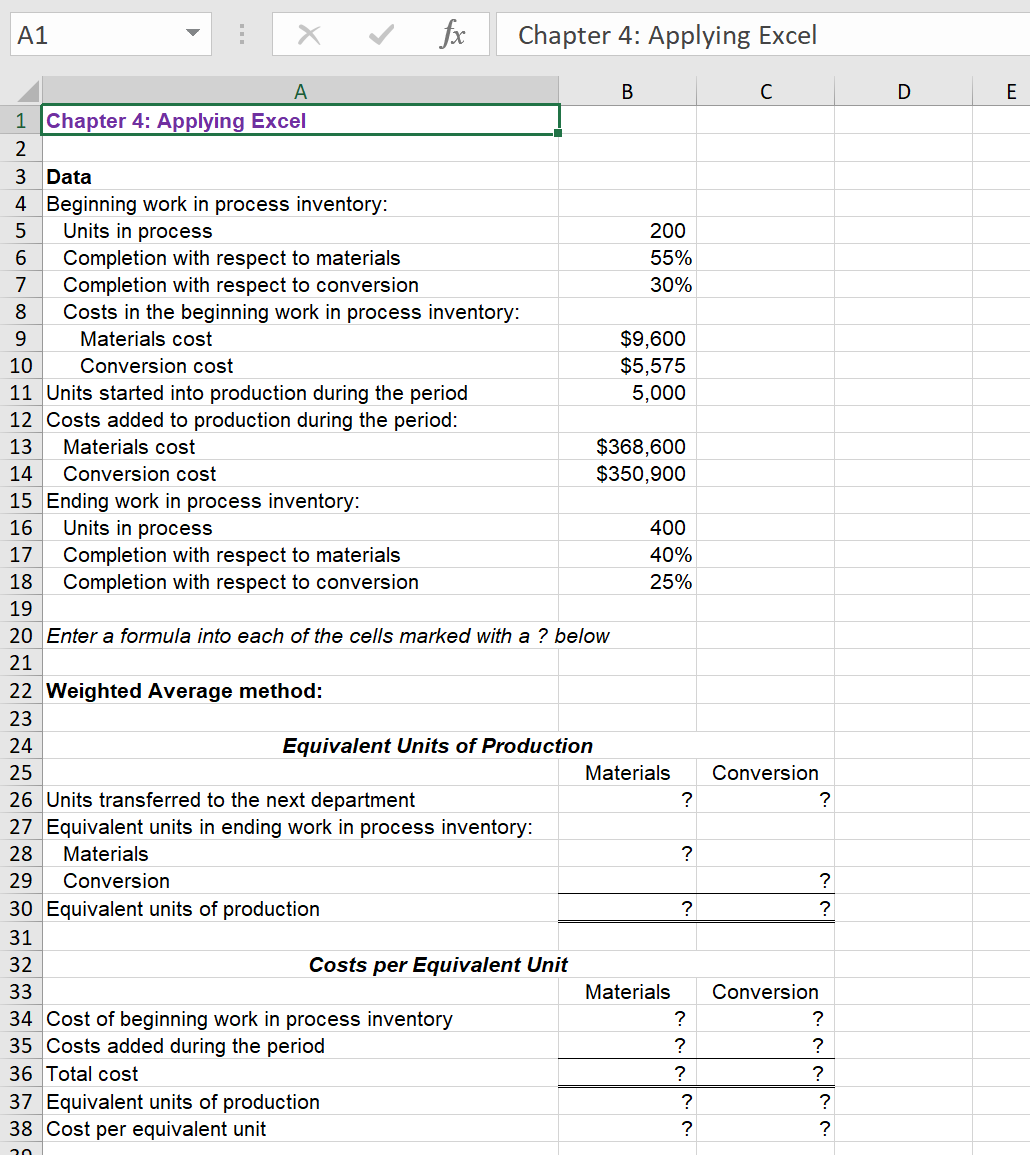

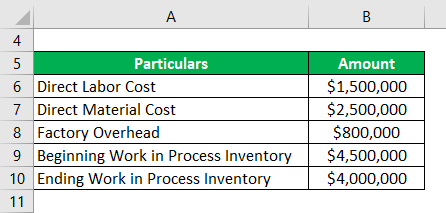

First we need to know our total costs for the period by adding beginning work.

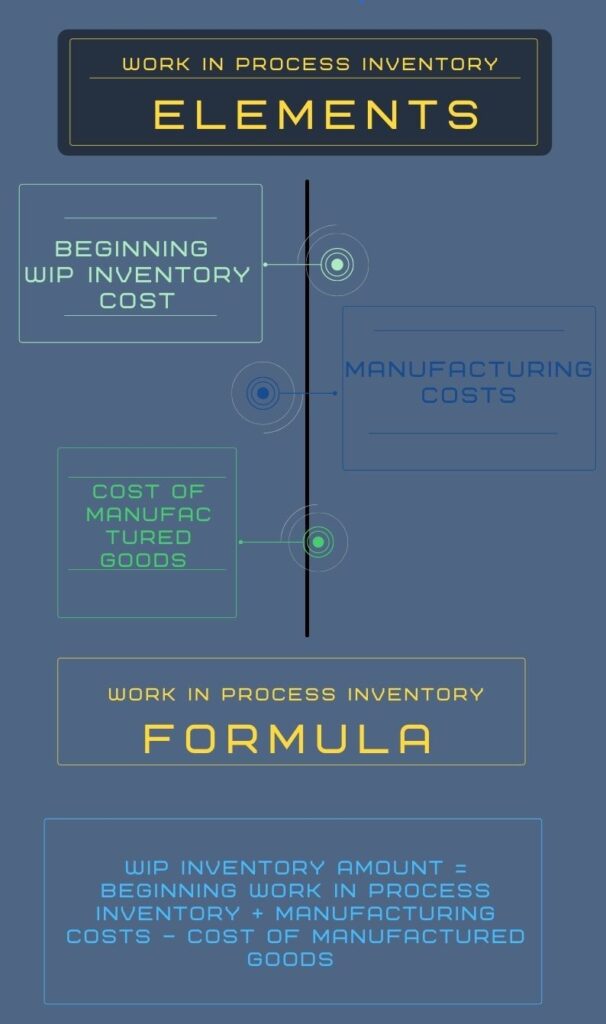

. Work in process WIP inventory refers to materials that are waiting to be assembled and sold. Work-in-process inventory refers to the partially completed materials within a production line. The work-in-process formula is expressed as.

As determined by previous accounting records your companys beginning WIP is 115000. Additionally items that are considered work in progress may depreciate or face a lower demand from consumers once they have been completed. Work-In-Progress Opening WIP Manufacturing Costs Cost of Goods Converted to.

Ending Inventory is calculated. Examples of Inventory Formula. Work In Progress - WIP.

Any raw material inventory that. The work-in-process formula. Any raw material inventory that humans have worked on but is not yet considered a finished good is a work-in-process inventory.

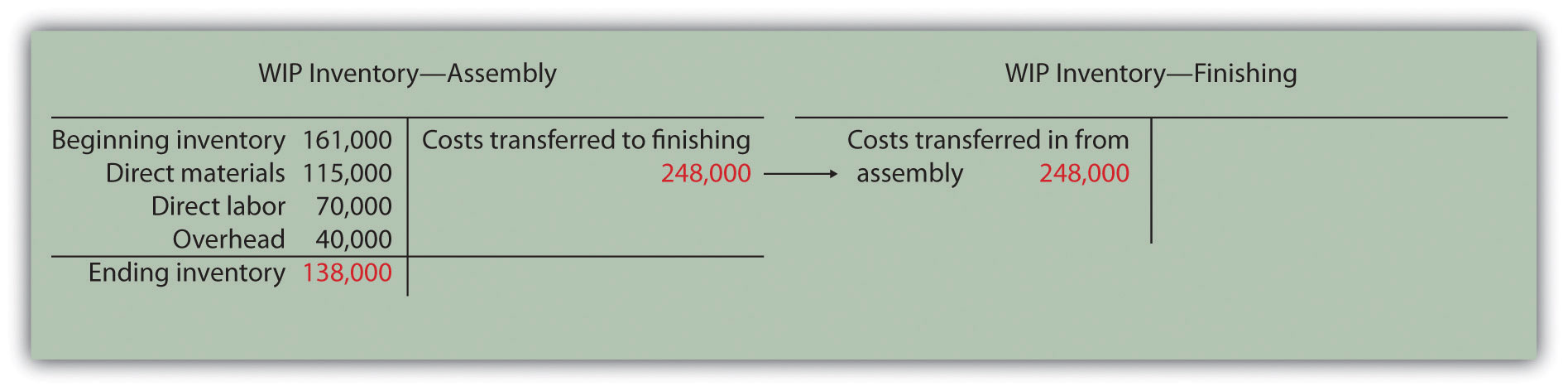

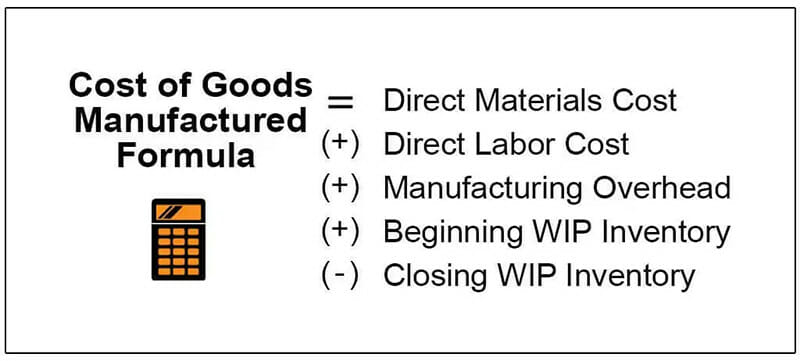

Opening work in process inventory formula Tuesday June 14 2022 Edit. Ending WIP Beginning WIP Manufacturing costs - Cost of goods produced. WIP is calculated as a sum of WIP inventory total direct labor costs and.

Determine the cost of goods sold COGS using your previous accounting periods records. Under this method the cost of. Definition formula and benefits.

You can think of WIP inventory as all inventory that has not yet. The amount of ending work in process must be derived as part of the period-end closing process and is also useful for tracking the volume of production activity. WIP inventory includes the cost of raw.

Work in process WIP inventory is a term used in production and supply chain management to refer to any materials or components that are waiting to be. WIP Inventory Example 2. Lets break down the steps for how to find beginning inventory.

Wip Inventory Definition Examples Of Work In Progress Inventory. Work in progress WIP sometimes referred to as work in process is the sum of all costs put into the production process to manufacture products that. Usually companies can calculate the value of WIP inventories by using the following formula.

Abnormal gain- Physical units 100 complete. During the year 150000 is spent on manufacturing. Work In Process Wip Inventory.

In this case for example consider any manufactured goods as work in process. Every dollar invested in unsold inventory. The work in process formula is the beginning work in process amount plus manufacturing costs minus the cost of manufactured goods.

Inventory can be finished goods Work in process goods or raw material. Abnormal loss- Physical units produced are multiplied by the degree of completion. The standard work in process inventory definition is all the raw material overhead costs and labor associated with every stage of the production process.

Cost Of Goods Manufactured Cogm Formula Calculation

Work In Progress Wip Definition Example Finance Strategists

All You Need To Know About Wip Inventory

Work In Progress Wip What Is It

All You Need To Know About Wip Inventory

Accounting Treatment Of Work In Progress Explanation Examples Finance Strategists

How To Calculate The Cost Of Goods Manufactured Cogm Mrpeasy

Answered Check Your Worksheet By Changing The Bartleby

What Is Work In Process Wip Inventory Eswap

Cost Of Goods Sold And The Income Statement For Manufacturing Companies Accounting In Focus

Valuation Of Work In Progress Ebookskenya

What Is Closing Stock Examples Calculations Tally Solutions

Work In Process Wip Inventory Youtube

Inventory Guide What Is Inventory

Calculation Of Turn Over Ratios For Work In Progress Inventory Download Table

Cost Of Goods Manufactured Formula Examples With Excel Template

How To Calculate Finished Goods Inventory

Wip Inventory Definition Examples Of Work In Progress Inventory